Don’t want to buy another expensive tool for the shed?

Don’t want to buy another expensive tool for the shed?

Are you using your drill to the fullest potential?

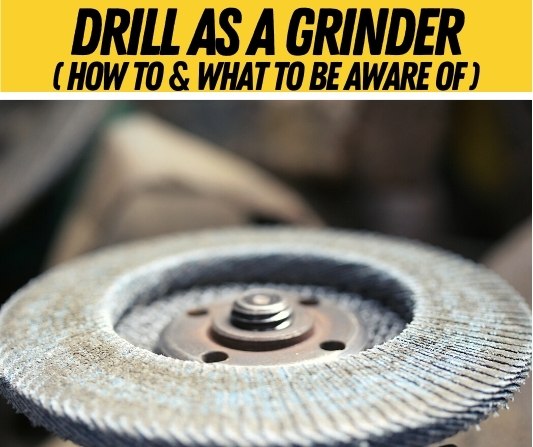

Need to sharpen some rusty or worn out tools? In this article I will show you how to turn your everyday drill into a tool sharpening station or a grinder so that you can get the best value out of your drill.

How to use a drill as a grinder

There can be many reasons why you may need grinder, whether it is to shave the rust off a metal part, polishing and cutting tiles, or even fix your ugly paint jobs here and there, you can accomplish all that without dropping your wallet on an actual grinder. Grinders are pretty pricey and if you do not plan on using it for a lot of jobs then you would be better off with a grinding attachment.

These attachments allow you to convert your drill into a grinder by simply plugging the attachment into the drill head. There are safety precautions and limitations to what a drill grinder can do as this is only a quick alternative as you most definitely won’t be able to get full grinder capabilities out of your drill.

How to turn the drill into an angle grinder

There are a few things that you will need to purchase unless you magically have them lying around your garage somewhere. They include a grinding wheel & and a drill arbor adapter. The drill is self explanatory and the grinding wheel depends on the size of the arbor adapter. A drill arbor adapter is basically a long screw that comes with two washer discs and a screw. The sizes of each part varies but you should double check to see what size arbor (drill hole) fits in your drill. Most standard cordless drills have a drill arbor of ¼ inch diameter. Normally, the other side of the adapter has a slightly bigger diameter (like 1/2inch) so that other attachments like a cutter or grinder. After assembling the drill, there are many ways you can utilize the grinder; you can build a station or keep it on your hand if you need to move the grinder around.

How to attach a grinding wheel to your drill?

First thing to do after you grab all of your parts needed is to see which side fits into the drill head. After that, take a look at the adapters and check if only one or two screws are used as it will tell you on how to install the grinder onto the adapter. If there is a separate screw that goes into the other half of the adapter(should be shaped like a hole) then simply attach the grinding wheel onto the lone screw and then attach it back into the adapter.

Make sure to tighten the adapter end so that the wheel does not wobble when in use. However, if your adapter only comes in one long screw with two washers and nuts, loosen up the nut on the adapter with the ½ shank and slide the grinding wheel in. After that slip the washer and nut back into the screw and tighten it all the way to prevent slippage. When you use the grinder, make sure to always wear gloves and safety glasses to prevent injury to the eyes and skin. When you slip the adapter back into the drill head, be sure to tighten the drill head once it is fully in.

Some drills have a special screwdriver made specifically for the drill head. If that is the case then make sure to fully insert the arbor adapter in and use the screwdriver to tighten the holes on the drill head. This same assembly method can also be used for putting on other attachments like a wire brush for polishing, a metal cutter to cut tile, wood and metal, or sandpaper for sanding and buffing.

If you do not feel like going out and buying the grinding attachment and you only need to sharpen a small item, I will show you how to make a one time grinding wheel from an old CD and sandpaper. Be aware that this will be only suitable for sharpening/grinding small items and even then It won’t be that good…

First, take the CD and trace it out on the sandpaper (make sure to trace twice). Then use a sharp tool to carve out the center hole big enough for a screw to fit in. Slip one layer of sandpaper into the screw along with a washer and then insert the CD inside. You may apply glue to tape the layers but it is not as the centripetal force will push the paper back. Insert a nut and another washer and tighten both ends with a wrench. Lastly, insert the screw end into the drill and tighten. This method will work if you only need to sharpen small bits and will not work against big projects like polishing mortar or cutting something!

Related: How to use a Drill as a Dremel

How to use drill as a grinder

When operating the grinder there are a few safety tips that you should keep in mind if you still want to keep your hands and fingers after this. Rule number one is to always unplug the drill or make sure it is switched off whenever you change out the wheel. The second rule is to never apply pressure while you are grinding. This is because the speed will take care of the hard lifting and pressing down will only break the wheel in pieces causing the shard to possibly cut your eyes.

The third rule is to never aim the wheel at a very sharp angle as this can jam the wheel into the material causing the wheel and the drill to break apart. Depending on the material you use to grind the angle should be 20-30 degrees. If you are cutting, then the wheel should be 90 degrees straight down towards the material. Sanding material away should be at a 5-10 degree angle and the wheel should only be touching by about one inch. If using a wire brush, also keep a 5-10 degree angle and only let the tip of the wire brush come in contact with the material. The last rule is to always make sure the wheel stops spinning before you set the drill grinder down on the table.

What you should be aware of.

When using the drill as a grinder, you will not have as much stability as if you bought a regular angle grinder. This is due to the extra handle in the angle grinder not being present on the drill. Another thing to consider is that when you grind metal with metal, sparks will fly out so wear heat resistant gloves. When choosing the right grinding wheel, it is important to check the max rpm of your drill and the wheel. The grinding wheel max rpm must be greater than the max rpm of the drill or else the wheel can shatter & fly off the drill and rickshade as it comes into contact with something since the speed is too much to handle. Also, be aware that a drill just won’t have enough power to cut large items and it will be Considerably slower than an actual angle grinder.

Best grinder attachments for drill

For all purpose grinding, such as cleaning up metal or sharpening tools, I recommend a standard grinding wheel as it is a one size fits all.

For cutting metal, the cutting grinding wheel is the best one for this job as it is very sleek and sharp. There is a higher chance of this wheel snapping and bending since the thickness is smaller than a standard wheel.

For cleaning paint and rust, the wire brush wheel will finish the job faster than any other grinding wheel. Wires tend to fly off this wheel over time and can scratch the skin pretty hard without protection. Make sure to choose a high quality wheel for this one and do not cut corners on price.

Also Read: How To Cut Metal Wire Without Wire Cutters

Metal grinding attachment for drill

If the size of your job is not gigantic, this metal grinding attachment will suffice rather than attaching a big wheel onto your drill. This piece goes for a few bucks and its small shape allows you to use the drill to curve and shape metal.